Decision Making

2008

Repower Resources

Westerbeke 44B Drawings |

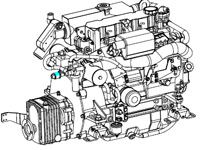

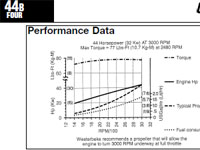

Westerbeke 44B Specifications |

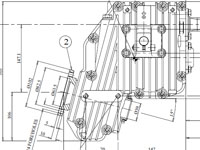

ZF-15 Installation |

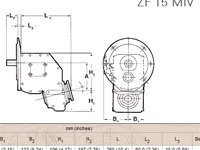

ZF-15 Drawings |

Repower Costs – 2008

| Cost Summary – Repower 2008 | |

|---|---|

| Major Parts and Equipment | $ 11,605 |

| Other Parts | $ 374 |

| Expendables | $ 878 |

| Services | $ 3,577 |

| Tools bought for this project | $ 582 |

| Total | $ 17,017 |

| Details | Cost | Sources |

| Major Parts and Equipment | ||

| 44B Engine | 9845.00 | Valiant |

| Exhaust elbow | 96.83 | Valiant |

| Aqua lift muffler | 198.40 | Valiant |

| Through hull | 43.47 | Valiant |

| Exhaust parts | 11.09 | Ace HW / Park Central |

| Exhaust hose | 95.00 | BOW |

| Exhaust hose -2 7′ | 101.71 | BOW |

| Fuel system parts | 231.90 | BOW / gotomarine |

| Aluminum rails | 86.81 | Online Metals |

| Shaft coupler | 65.25 | Bobby Soles Propellor Service |

| Compressor bracket | 87.50 | SeaFrost |

| Compressor bracket base | 61.43 | Online Metals |

| Cutlass Bearing | 74.33 | Bobby Soles Propellor Service |

| Vented loop | 94.99 | BOW |

| Sani hose | 72.00 | WM |

| Fuel hose – 5/16 – 12′ | 33.84 | BOW |

| Fuel hose – 1/4 – 1′ | 1.54 | BOW |

| Water hose – 1 – 12′ | 84.12 | BOW |

| Water hose – 1/2 | 17.89 | BOW |

| Water hose – 5/8 | 14.63 | WM |

| Water hose – 3/4 bilge | 74.76 | BOW |

| Water hose – 1/2 – 25′ | 28.00 | BOW |

| Condensor hoses | 108.00 | Seafrost |

| 1 hose (condensor) | 77.00 | BOW |

| 11605.49 | ||

| Other Parts | ||

| Hose adapter | 6.80 | BOW |

| Fuel adapters | 6.94 | BOW |

| Hose clamps – 5/16 – 6 | 17.58 | BOW |

| Hose clamps – 2 – 6 | 29.94 | BOW |

| Hose clamps – #16 – 12 | 19.80 | BOW |

| Brass tee and plug | 15.69 | BOW |

| Brass plumbing hw | 29.33 | BOW |

| Electrical | 11.04 | BOW |

| Misc. plumbing | 49.22 | BOW |

| Misc Electrical | 65.70 | WM |

| Dolly parts | 65.00 | HD |

| Drive belt | 18.00 | Pep Boys |

| Shaft seal o-rings & screws | 4.00 | PYI |

| Maxprop screws | 22.00 | PYI |

| Ring connectors | 3.09 | WM |

| Hose hangers – 1 | 10.11 | WM |

| 374.24 | ||

| Expendables | ||

| Bottom paint | 299.98 | Defender |

| Woven roving | 14.98 | Defender |

| Bilge paint | 19.99 | Defender |

| Floor protection | 23.39 | HD |

| Bed mockup supplies | 28.07 | WM |

| Misc epoxy stuff | 16.00 | WM |

| Vacuum cartridge | 18.10 | Sears |

| Zinc Chromate primer | 17.03 | WM |

| Red Engine paint | 5.49 | Pep Boys |

| Lifting frame | 30.71 | Lowes |

| Template parts | 13.00 | HD |

| Rags | 10.97 | HD |

| Sanding disks | 9.97 | HD |

| Maxprop grease @8 | 16.00 | PYI |

| West Resin | 32.00 | Seminole |

| West Hardener | 19.61 | WM |

| Grinding wheels | 16.90 | Lowes |

| Abrasive disk | 8.97 | HD |

| 6 glass tape | 17.00 | WM |

| Sandpaper | 9.48 | Ace |

| Mineral spirits | 6.99 | Ace |

| Dust masks | 14.98 | Ace |

| Hacksaw blades | 3.58 | Ace |

| Threadlock | 3.79 | Ace |

| Jigsaw blades | 8.91 | Ace |

| Bunny suit / shoe cover | 16.98 | WM |

| Rail paint | 5.49 | Pep Boys |

| Misc. sealants | 8.48 | Pep Boys |

| Brushing thinner | 49.99 | BOW |

| Epoxy Barrier Kote | 31.99 | BOW |

| Sandpaper | 5.10 | BOW |

| Bunny suit | 7.00 | Seminole |

| Life Caulk | 21.29 | WM |

| Antifreeze | 16.00 | Walmart |

| ATF | 7.54 | Walmart |

| 15W40 Rotella – 5q | 23.43 | BOW |

| Silicone | 8.49 | Seminole |

| Paint rollers | 9.98 | WM |

| 877.65 | ||

| Services | ||

| Engine shipping | 486.99 | Fedex |

| T-hull shipping | 10.54 | UPS |

| Paint shipping | 22.88 | UPS |

| Haul and blocking | 340.00 | Seminole |

| Crane | 150.00 | Seminole |

| Pwash | 100.00 | Seminole |

| Yard storage | 2140.00 | Seminole |

| Electric | 180.00 | Seminole |

| Environmental fee | 35.00 | Seminole |

| Block moving | 37.50 | Seminole |

| Shaft fit&face | 65.00 | Bobby Soles Propellor Service |

| PYI Shipping | 9.00 | UPS |

| 3576.91 | ||

| Tools purchased for this project | ||

| Shop crane | 129.00 | Pep Boys |

| Load leveler | 50.00 | Pep Boys |

| Digital level | 35.00 | Sears |

| Photo tach | 60.69 | Harbor Freight |

| Puller set | 11.70 | Harbor Freight |

| Reefer gauge set | 45.78 | Harbor Freight |

| Grinder | 30.87 | Harbor Freight |

| Hole saw | 24.68 | HD |

| Misc shackles etc. | 10.00 | HD/Lowes |

| Rod and hw for cutlass | 8.73 | Ace |

| Parts for cutlass remove | 2.26 | Lowes |

| 6′ stepladder | 39.99 | HD |

| Ladder mate | 9.99 | HD |

| Long drill bit | 7.79 | Ace |

| Pressure gage | 8.99 | Ace |

| 1/2×13 die | 5.79 | Ace |

| Vacuum Pump | 84.98 | Harbor Freight |

| Maxprop grease gun | 16.00 | PYI |

| 582.24 | ||

| TOTAL | 17016.53 |

Repower Project – 2008

Starting in June 2008, we upgraded Windwalker with a new engine. After a lot of dockside work, 37 days on the hard, and another several months of finish-up work at the dock, we declared victory just prior to New Year’s of 2009. An extensive sea trial to the Florida Keys in the spring of 2009 completed the project.

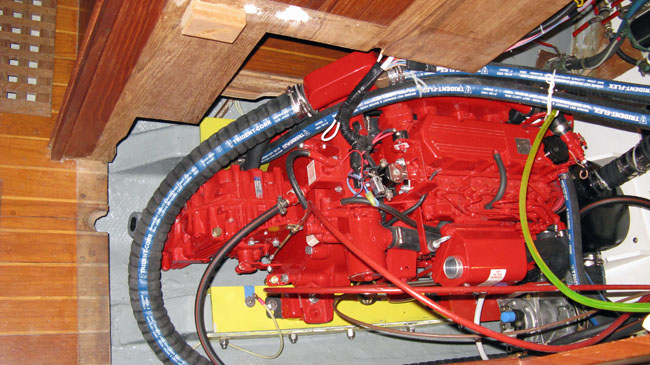

The new engine is a Westerbeke 44B, replacing a Volvo 2003T. Because the new engine is longer (4 cylinders versus 3), lower, and with a V-drive down-angle of 15 degrees instead of 20, the old beds had to be significantly modified. Other incompatibilities included a smaller exhaust size (2″ vs 2-1/4″), electrical connections and control cables on the opposite side, and interference with the bilge pump and fresh water systems components, to name a few. As you may expect – there was a bit of engineering involved. The space was modeled using Drafix CAD, and drawings were made for the beds and engine setup, and a template was constructed from plywood to insure engine alignment before committing to glass.

Cabinets and bulkhead components were removed, and work got started, but we didn’t haulout until everything was ready so as to minimize the yard time which was going to cost $80/day after the first month. All in all, the haulout and engine swap went fairly smoothly and took only a week longer than planned. With temporary plumbing, electrical hookups and instrument panel, we splashed in October and made our way back to the dock (5 miles) under our own power. At the dock, we completed final plumbing and electrical, mounted the panel in the cockpit (which required the casting of a new fiberglass insert), mounted the refrigeration compressor and new hoses, hooking up the hot water heater, relocated the bilge pump, fresh water system, and oil change pump, and put all the woodwork back together.

It was an extensive and complex project as you might expect, but by doing all the work ourselves, it was not as expensive as it could have been. The engine was purchased from Valiant in Texas at a good discount, and drop shipped to us in Florida from the Westerbeke plant in Massachusets. Setups and measurements, as well as custom fabrication of the compressor bracket and other parts was done in our garage, while much tear-down was done at our dock prior to entering the yard.

For a step-by-step description, photographs, and an accounting of the costs involved, please see our project page.